Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

Chesapeake Machining & Fabrication, Inc. is a metal fabricator providing products and services to a variety of industries. We have capabilities in press brakes, shears, angle and shape rolls, iron working and welding. Contact us today for more information.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

Welcome to Washington Metal Fabricators, where we specialize in providing high-quality metal fabrication solutions to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as leaders in the industry, delivering innovative products and services tailored to exceed our clients' expectations. Our core expertise lies in metal...

At Fabri-Tech, Inc., we pride ourselves on being a premier provider of metal fabrication solutions, catering to the diverse needs of our valued clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of metal...

More Steel Fabricator Companies

Steel fabricators are professionals who create structures and parts made from steel. They play a crucial role in construction projects by cutting, shaping, and joining steel pieces to form large and complex structures. Together, we will explore many topics relating to steel fabricators, including the objects they work on tools and techniques of their trade, their employment and education, the advantages of using steel fabricators, and the applications of their work.

Objects Steel Fabricators Work On

Steel fabricators are typically hired to work on a wide range of projects that involve the fabrication, assembly, and installation of steel structures and components. These may include everything from large-scale commercial and industrial projects like bridges, skyscrapers, and stadiums, to smaller residential projects like custom staircases, railings, and decorative metalwork. Some common objects that steel fabricators are hired to work on include structural steel components like beams, columns, and trusses, as well as custom metalwork like gates, fences, and ornamental features.

Tools Steel Fabricators Use

To create these objects, steel fabricators typically use a variety of tools that are specific to the trade. These may include:

Cutting Tools

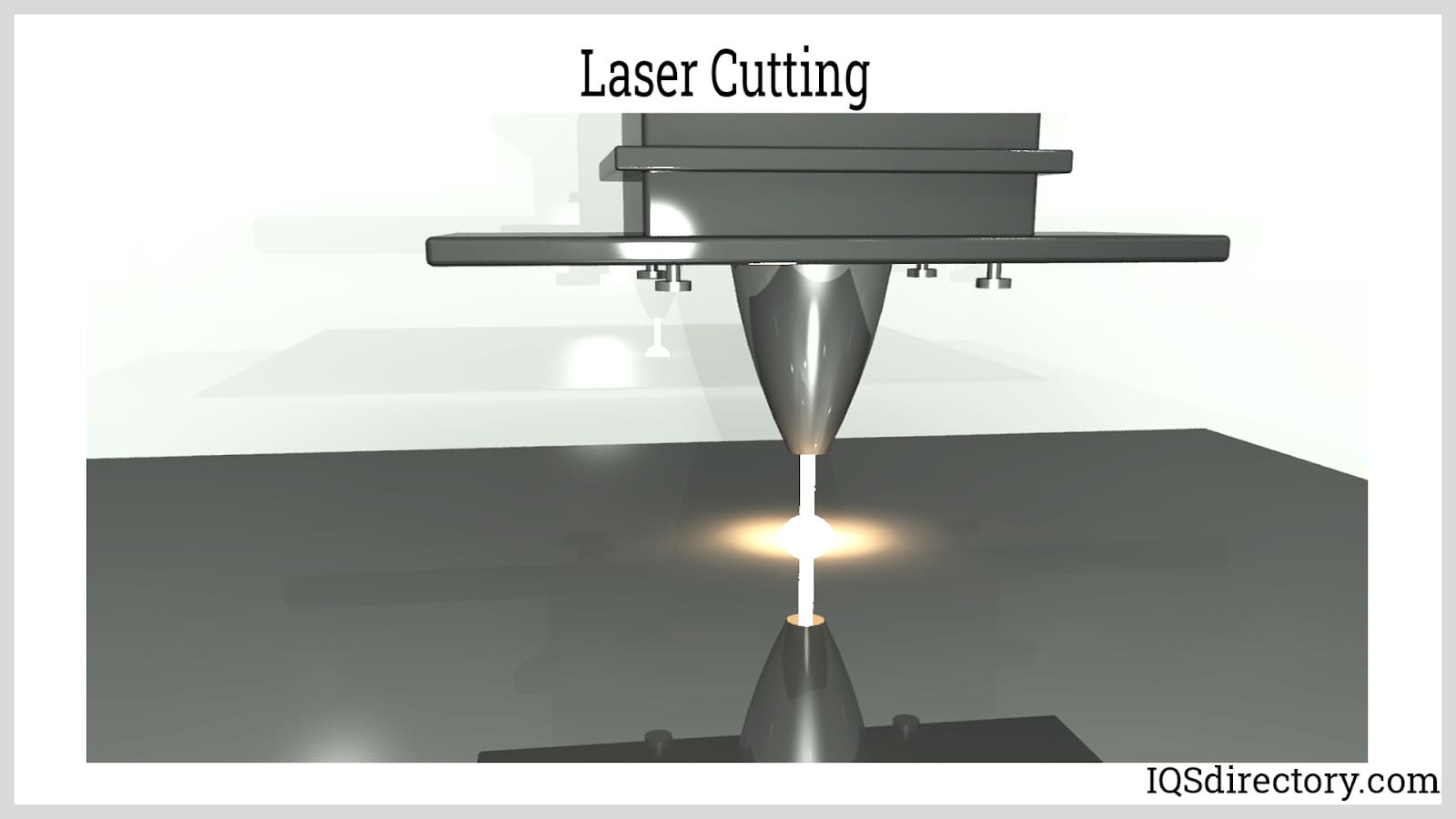

Steel fabricators use a range of cutting tools to cut and shape steel, including plasma cutters, oxy-acetylene torches, and shears.

Welding Tools

Welding is an essential process in steel fabrication, and fabricators use a range of welding tools to join steel components together, including arc welders, MIG welders, and TIG welders.

Bending and Forming Tools

To create curved or angled components, steel fabricators use bending and forming tools like brakes and rollers.

Computer-Aided Design (CAD) Software

Many steel fabricators use CAD software to create detailed designs and models of steel structures and components before fabrication begins.

Lifting and Rigging Equipment

Steel components can be heavy and unwieldy, so fabricators often use lifting and rigging equipment like cranes and hoists to move them into place.

Finishing Tools

To give steel components a smooth, polished finish, fabricators may use sanders, grinders, and other finishing tools. Overall, steel fabricators are skilled tradespeople who use a wide range of specialized tools to create a variety of steel structures and components.

Employment and Education of Steel Fabricators

Steel fabricators can be employed on a full-time, part-time, or contract basis. They may work in manufacturing plants, construction sites, or metal fabrication shops. Some steel fabricators work independently or run their own fabrication businesses. To become a steel fabricator, one may pursue an apprenticeship, technical training, or a college degree in welding or metal fabrication.

Considerations When Employing a Steel Fabricator

If you're planning to use or employ a steel fabricator for your project, here are some considerations you should take into account:

Experience and Expertise

Look for a steel fabricator who has extensive experience in the type of fabrication you require. This ensures that they have the necessary knowledge and expertise to complete your project efficiently and to the highest quality.

Capacity and Equipment

Check if the fabricator has the capacity and equipment required to handle your project. This includes having the necessary machinery, workforce, and resources to fabricate the steel components required for your project.

Quality Assurance

Ensure that the fabricator has a robust quality assurance process in place. This involves checking their certification and quality standards to ensure that their work meets the required quality and safety standards.

Communication

Communication is key to a successful project, so make sure that the fabricator is willing to communicate with you regularly throughout the fabrication process. This ensures that you are aware of any issues or delays that may arise and can make adjustments as necessary.

Cost and Delivery Time

Obtain multiple quotes from different fabricators to compare costs and delivery time. This allows you to select a fabricator that offers a competitive price while still meeting your delivery requirements.

References

Check the fabricator's references, including past clients and completed projects, to ensure that they have a good reputation and track record of delivering high-quality work. By taking these considerations into account, you can select a steel fabricator who can deliver the required components for your project on time and to the highest quality standards.

Benefits of Using Steel Fabricators

There are several benefits to using and hiring steel fabricators, including:

Expertise and Experience

Steel fabricators have the expertise and experience needed to work with steel and other metals, ensuring that your project is completed to the highest standards.

Customization

Steel fabricators can create customized solutions for your project, ensuring that it meets your exact specifications and needs.

Versatility

Steel fabricators can be used for a wide range of applications, from construction to manufacturing to transportation.

Applications of Steel Fabricators

Due to their training and expertise, steel fabricators may find applications in the following areas:

Construction

Steel fabricators are commonly used in the construction industry to build everything from bridges and skyscrapers to stadiums and parking garages.

Manufacturing

Steel fabricators are also used in the manufacturing industry to produce a wide range of products, including automotive parts, appliances, and machinery.

Infrastructure

Steel fabricators are used to create infrastructure projects such as roadways, railways, and airports..

Agriculture

Steel fabricators are commonly used in the agricultural industry to build barns, storage facilities, and other structures.

Transportation

Steel fabricators play a critical role in the transportation industry by fabricating and assembling various steel components used in the construction of bridges, highways, railroads, and other transportation infrastructure.

Choosing the Right Steel Fabricator

To ensure you have the most beneficial outcome when choosing a steel fabricator, it is important to compare several steel fabricators using our directory of steel fabricator businesses. Each steel fabricator has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the business for more information or to request a quote. Review each steel fabricator business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple steel fabricators with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services