Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

Chesapeake Machining & Fabrication, Inc. is a metal fabricator providing products and services to a variety of industries. We have capabilities in press brakes, shears, angle and shape rolls, iron working and welding. Contact us today for more information.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

Welcome to Washington Metal Fabricators, where we specialize in providing high-quality metal fabrication solutions to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as leaders in the industry, delivering innovative products and services tailored to exceed our clients' expectations. Our core expertise lies in metal...

At Fabri-Tech, Inc., we pride ourselves on being a premier provider of metal fabrication solutions, catering to the diverse needs of our valued clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of metal...

More Custom Metal Fabrication Companies

Metal fabrication is the process of transforming raw metal materials into finished products using various tools, techniques, and processes. The applications of metal fabrication are vast and can be seen in many industries such as construction, automotive, aerospace, and manufacturing. Custom metal fabrication, on the other hand, involves creating unique and tailored metal products based on specific design requirements.

Considerations for Metal Fabrication

When it comes to metal fabrication, several considerations need to be taken into account. Material selection is one of the most critical considerations as different metals have different properties and characteristics that can impact the final product. Equipment and tools also play an important role in metal fabrication, as the right tools are necessary for precise and accurate cuts, bends, and welding. Safety considerations are also essential to prevent injuries and accidents in the workplace. Design and cost considerations are also important as they can affect the final product's functionality and pricing.

Considerations for Custom Metal Fabrication

Since custom metal fabrication involves creating unique metal products based on specific design requirements, it presents its own, unique challenges. One of the key considerations for custom metal fabrication is material availability, as custom designs may require specific materials that are not readily available. Design specifications and custom tooling requirements are also critical considerations for custom metal fabrication, as unique designs require unique tooling and techniques. Time and cost considerations are also essential, as custom metal fabrication can be more time-consuming and expensive than standard metal fabrication.

Benefits of Metal Fabrication

The benefits of metal fabrication are numerous. Customization is one of the most significant benefits of metal fabrication, as it allows for the creation of unique and tailored metal products based on specific design requirements. Durability is also a key benefit of metal fabrication, as metal is known for its strength and longevity. Versatility is another benefit of metal fabrication, as it can be used in a wide range of applications. Finally, metal fabrication can also be cost-effective, especially when compared to other manufacturing processes.

Benefits of Custom Metal Fabrication

Custom metal fabrication offers several additional benefits over standard metal fabrication. Unique design capabilities are one of the most significant benefits of custom metal fabrication, as it allows for the creation of custom metal products that stand out from the crowd. Precision and accuracy are also essential benefits of custom metal fabrication, as custom designs require precise and accurate cuts, bends, and welding. Material optimization is another benefit of custom metal fabrication, as it allows for the use of materials in the most efficient way possible. Finally, custom metal fabrication also offers improved functionality, as custom designs can be tailored to meet specific needs and requirements.

Applications of Metal Fabrication

Metal fabrication has a wide range of applications, including automotive and transportation, construction, manufacturing, and aerospace and defense. In the automotive and transportation industry, metal fabrication is used to create various parts, including frames, chassis, and body panels. In construction, metal fabrication is used to create structural steel beams, staircases, and railings. In manufacturing, metal fabrication is used to create a wide range of products, including machinery, equipment, and tools. Meanwhile, custom metal fabrication is extensively used in aerospace and defense to create precision parts and components for aircraft, spacecraft, and military equipment.

Applications of Custom Metal Fabrication

Custom metal fabrication build upon these applications and includes:

Architectural and Decorative Elements

Custom metal fabrication is commonly used to create unique architectural and decorative elements for homes, commercial buildings, and public spaces. These elements may include metal screens, metal panels, metal artwork, metal railings, and metal sculptures. Custom metal fabrication allows for the creation of unique designs that can be tailored to match the style of the building or space.

Medical Equipment and Devices

Custom metal fabrication is often used in the medical industry to create specialized equipment and devices, including dental implants, orthopedic implants, surgical instruments, and diagnostic equipment. Custom metal fabrication allows for the creation of precise and accurate components that are essential for these types of devices.

Custom Furniture

Custom metal fabrication is used in the creation of unique and one-of-a-kind furniture pieces, including tables, chairs, and lighting fixtures. Metal can be combined with other materials such as wood, glass, and stone to create stunning and functional furniture pieces.

Artistic and Sculptural Projects

Custom metal fabrication is commonly used in artistic and sculptural projects. Metal's malleability and strength make it an ideal material for creating complex and intricate designs. Custom metal fabrication allows for the creation of unique and one-of-a-kind pieces of art and sculpture that are often used for public installations, museums, and galleries.

Custom Automotive Parts and Accessories

Custom metal fabrication is used in the automotive industry to create custom parts and accessories for cars, motorcycles, and other vehicles. These may include custom exhaust systems, roll cages, suspension components, and body panels. Custom metal fabrication allows for the creation of unique and high-quality parts that can improve a vehicle's performance and appearance.

Customized Industrial Equipment

Custom metal fabrication is used to create customized industrial equipment and machinery for a wide range of industries, including manufacturing, construction, and agriculture. This may include customized conveyor systems, customized industrial pumps, and customized industrial valves. Custom metal fabrication allows for the creation of unique and specialized equipment that can improve efficiency and productivity.

Retail Displays

Custom metal fabrication is used in the creation of unique retail displays, including clothing racks, shelving units, and signage. Metal's durability and versatility make it an ideal material for creating visually appealing and functional displays.

Aerospace Components

Custom metal fabrication is used in the aerospace industry to create complex and precise components for aircraft, spacecraft, and satellites. These components may include structural components, fuel tanks, and propulsion systems. Custom metal fabrication allows for the creation of high-quality and reliable components that are essential for the aerospace industry.

Food and Beverage Equipment

Custom metal fabrication is used to create specialized equipment for the food and beverage industry, including commercial-grade kitchen equipment, brewery equipment, and beverage dispensing systems. Custom metal fabrication allows for the creation of equipment that meets specific health and safety standards while also being durable and efficient.

In conclusion, custom metal fabrication has a wide range of applications across various industries. It allows for the creation of unique and specialized products that are tailored to specific design requirements and can improve efficiency, performance, and appearance.

Choosing the Proper Custom Metal Fabricator

To ensure you have the most positive outcome when selecting a custom metal fabricator, it is important to compare several companies using our directory of custom metal fabricators. Each custom metal fabricator has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or to request a quote. Review each custom metal fabricator business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple custom metal fabricators with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

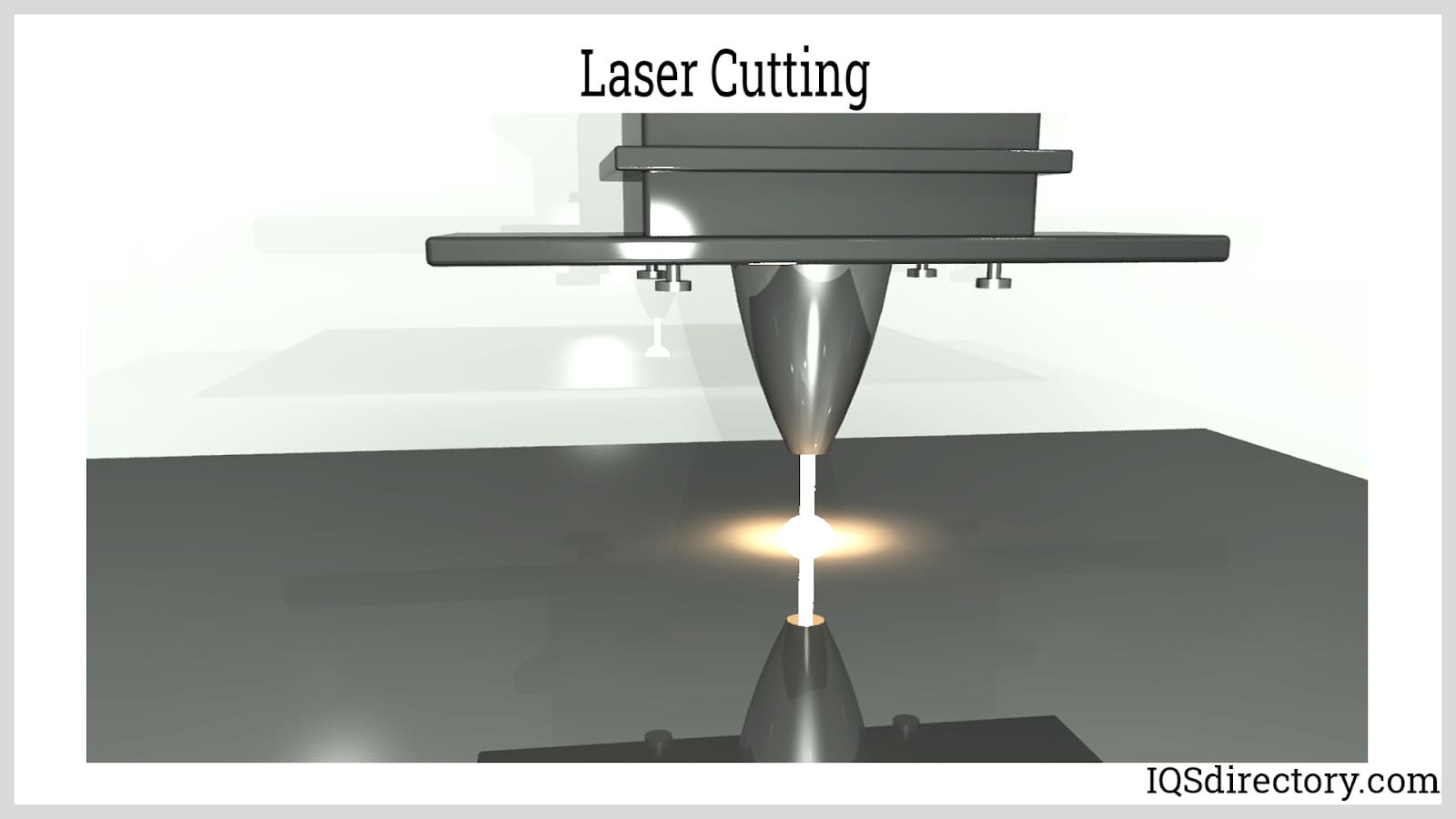

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services