Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

Chesapeake Machining & Fabrication, Inc. is a metal fabricator providing products and services to a variety of industries. We have capabilities in press brakes, shears, angle and shape rolls, iron working and welding. Contact us today for more information.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

Welcome to Washington Metal Fabricators, where we specialize in providing high-quality metal fabrication solutions to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as leaders in the industry, delivering innovative products and services tailored to exceed our clients' expectations. Our core expertise lies in metal...

At Fabri-Tech, Inc., we pride ourselves on being a premier provider of metal fabrication solutions, catering to the diverse needs of our valued clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of metal...

More Aluminum Fabricator Companies

Aluminum fabricators are professionals who specialize in the manufacturing of aluminum products or components. They typically work with aluminum alloy and use various fabrication techniques to create custom designs or products.

What Do Aluminum Fabricators Do?

Aluminum fabricators perform the process of aluminum fabrication. This involves a series of steps that may vary depending on the desired product or design. However, the primary processes include casting, extrusion, forging, and sheet metal forming. Casting is the process of pouring molten aluminum into a mold, while extrusion involves forcing a heated aluminum billet through a die to form a shape. Forging, on the other hand, is the process of heating and shaping the aluminum through pressure and dies, while sheet metal forming is the process of cutting and bending aluminum sheets.

Each process has its benefits and is related to specific applications. For instance, casting is ideal for large, intricate shapes that require strength, while extrusion is perfect for creating uniform shapes such as tubing and profiles. Forging is best for creating parts that require exceptional strength and durability, while sheet metal forming is ideal for creating complex, three-dimensional shapes.

Aluminum fabricators may specialize in one or more specific processes of aluminum fabrication, depending on their training, expertise, and the type of products or components they are manufacturing. While some aluminum fabricators may be proficient in all four processes of casting, extrusion, forging, and sheet metal forming, others may focus on one or two of these processes and subcontract other processes to specialists as needed.

For instance, an aluminum fabricator who specializes in casting may work with a subcontractor who specializes in sheet metal forming to create a finished product that requires both processes. Similarly, an aluminum fabricator who specializes in extrusion may subcontract the forging process to a specialist if required.

It's also worth noting that some aluminum fabricators may offer additional services such as design, prototyping, finishing, and installation, while others may focus solely on the manufacturing process. Ultimately, it depends on the individual aluminum fabricator's capabilities and the specific needs of the client or industry.

How Are Aluminum Fabricators Employed?

Aluminum fabricators can be employed in a variety of industries, including manufacturing, construction, aerospace, automotive, marine, and more. They can work for companies that specialize in aluminum fabrication or for businesses that require custom aluminum products for their operations. Some aluminum fabricators may also work as contractors or freelancers and may be hired as needed for specific projects or applications. It ultimately depends on the business needs and the type of aluminum products or components required.

Considerations for Selecting Aluminum Fabricators

Companies which hire their own, permanent, aluminum fabricators generally have well-established employment procedures and requirements. When selecting or hiring an aluminum fabricator as a contractor or freelancer, however, there are several considerations to keep in mind, including:

Expertise and Experience

Look for an aluminum fabricator with a track record of producing high-quality products that meet your specific requirements. Consider their experience and expertise in your industry or the type of product you need.

Capabilities

Ensure the aluminum fabricator has the equipment, technology, and expertise to handle the specific processes required for your project.

Quality Control

A reputable aluminum fabricator should have a robust quality control system in place to ensure that each product is manufactured to the highest standards.

Communication

Clear and effective communication is crucial for a successful project. Ensure that the aluminum fabricator can provide clear communication throughout the process and is responsive to any questions or concerns you may have.

Price

Consider the cost of the aluminum fabrication services, but don't make it the only deciding factor. Choosing the lowest-priced option may not always result in the best quality product or service.

Location

Consider the location of the aluminum fabricator, as shipping costs and lead times can be affected by distance. By keeping these considerations in mind, you can select an aluminum fabricator that can deliver high-quality products that meet your specific requirements, within budget and on time.

Benefits of Aluminum Fabricators

There are several benefits of using aluminum fabricators for manufacturing aluminum products or components. Here are a few key advantages:

Expertise and Experience

Aluminum fabricators have specialized knowledge and experience in working with aluminum materials and processes, which can ensure high-quality results and reduce the risk of errors or mistakes.

Customization

Aluminum fabricators can work with clients to create custom designs and products to meet specific requirements, ensuring a perfect fit and function.

Equipment and Technology

Aluminum fabricators often have access to advanced equipment and technology that can help streamline the manufacturing process and produce high-quality results.

Quality Control

A reputable aluminum fabricator should have a robust quality control system in place to ensure that each product is manufactured to the highest standards.

Efficiency

Aluminum fabricators can often produce products quickly and efficiently, reducing lead times and increasing productivity.

Cost-Effective

Aluminum fabricators can often provide cost-effective solutions for manufacturing aluminum products or components, especially for large-scale production runs.

Applications of Aluminum Fabrication

Aluminum fabricators can be used in a wide range of industries and applications. Here are some examples of their applications in various industries:

Automotive

Aluminum fabricators can be used in the production of automotive parts, such as wheels, chassis components, engine components, and body panels.

Aerospace

Aluminum fabricators can be used in the production of aerospace components, such as aircraft frames, wings, and fuselages.

Construction

Aluminum fabricators can be used in the production of building components, such as windows, doors, roofing, and structural frames.

Marine

Aluminum fabricators can be used in the production of marine components, such as boat hulls, decks, and masts.

Consumer Goods

Aluminum fabricators can be used in the production of various consumer goods, such as electronics, furniture, sporting equipment, and household appliances.

Medical Equipment

Aluminum fabricators can be used in the production of medical equipment, such as hospital beds, wheelchairs, and surgical instruments.

Choosing the Correct Aluminum Fabricator

To ensure you have the most beneficial outcome when choosing an aluminum fabricator, it is important to compare several companies using our directory of aluminum fabricators. Each aluminum fabricator has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or to request a quote. Review each aluminum fabricator business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple aluminum fabricators with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

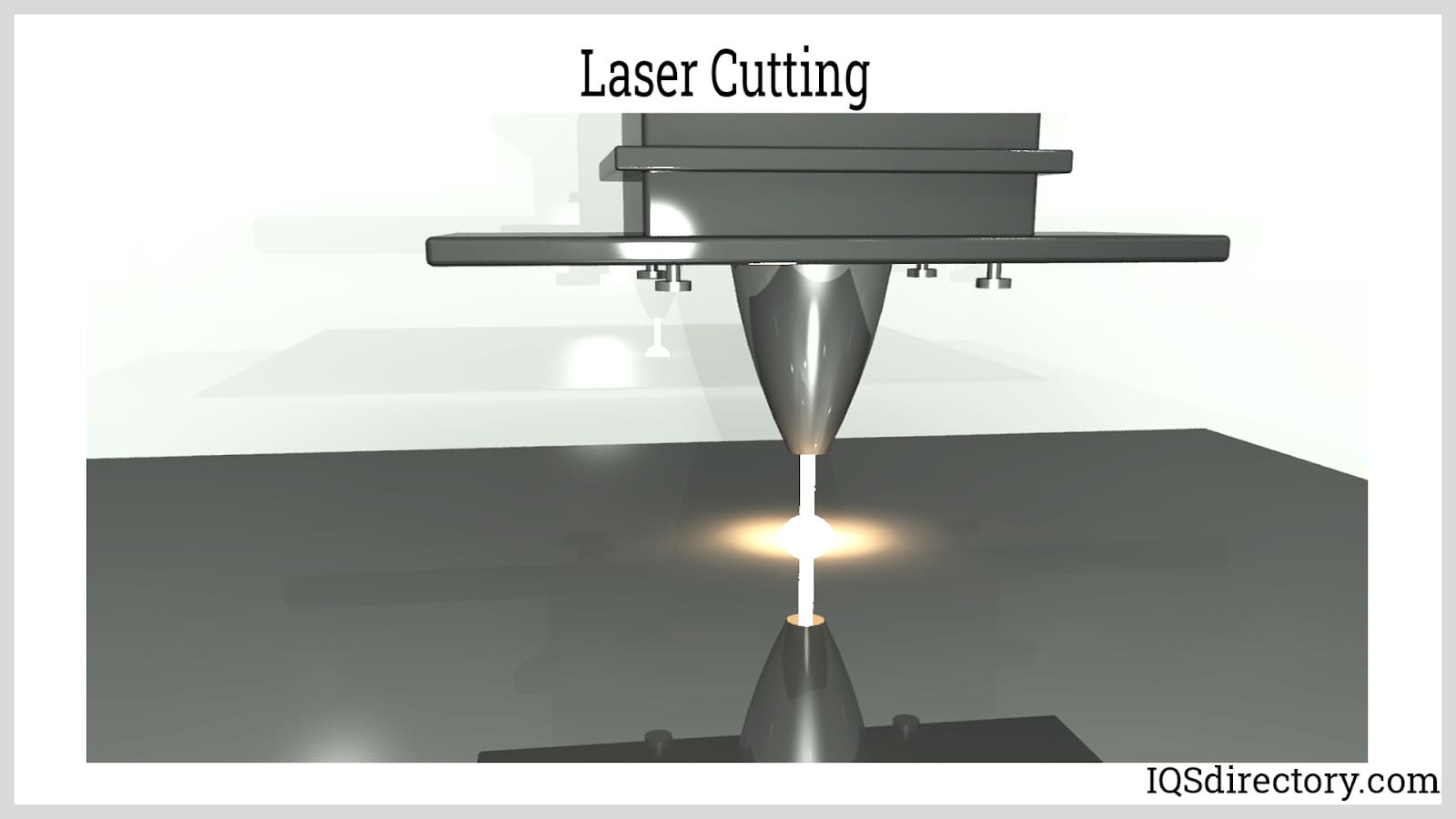

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services