Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

Chesapeake Machining & Fabrication, Inc. is a metal fabricator providing products and services to a variety of industries. We have capabilities in press brakes, shears, angle and shape rolls, iron working and welding. Contact us today for more information.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

Welcome to Washington Metal Fabricators, where we specialize in providing high-quality metal fabrication solutions to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as leaders in the industry, delivering innovative products and services tailored to exceed our clients' expectations. Our core expertise lies in metal...

At Fabri-Tech, Inc., we pride ourselves on being a premier provider of metal fabrication solutions, catering to the diverse needs of our valued clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of metal...

More Stainless Steel Fabricator Companies

Stainless steel fabrication is a process of shaping, cutting, and transforming stainless steel material into various forms and structures, including tanks, piping systems, equipment, and machinery. Stainless steel is a popular choice for fabricators because of its durability, resistance to corrosion, and aesthetic appeal.

What Do Stainless Steel Fabricators Do?

Stainless steel fabricators are professionals who specialize in transforming stainless steel material into functional and aesthetically pleasing products. They use various tools and equipment to fabricate, shape, and weld stainless steel parts and components.

How Are Stainless Steel Fabricators Employed?

Stainless steel fabricators may work for large manufacturing companies, small businesses, or as independent contractors. They may work in various industries and serve various applications. Many applications of stainless steel fabricators are discussed in greater detail below.

Construction

Stainless steel is often used in the construction industry for its durability, corrosion resistance, and aesthetic appeal. Stainless steel fabricators may produce components such as handrails, balustrades, and structural elements like beams, columns, and trusses.

Food Processing

Stainless steel is a popular material in the food processing industry due to its ability to resist corrosion and staining. Stainless steel fabricators may produce equipment such as mixing tanks, conveyor systems, and processing machinery used in food production.

Medical Equipment

Stainless steel is also used in medical equipment due to its corrosion resistance and hygienic properties. Stainless steel fabricators may produce components such as surgical tools, dental instruments, and diagnostic equipment.

Automotive

Stainless steel is used in the automotive industry for its corrosion resistance and strength. Stainless steel fabricators may produce components such as exhaust systems, fuel tanks, and suspension components.

Aerospace

Stainless steel is used in the aerospace industry due to its strength-to-weight ratio and resistance to high temperatures. Stainless steel fabricators may produce components such as structural elements, fuel tanks, and engine components.

Marine

Stainless steel is used in the marine industry for its corrosion resistance and durability. Stainless steel fabricators may produce components such as propellers, anchors, and marine hardware.

Consumer Products

Stainless steel is commonly used in consumer products such as appliances, kitchenware, and furniture due to its aesthetic appeal and durability. Stainless steel fabricators may produce components such as handles, frames, and decorative elements.

Considerations Regarding Stainless Steel Fabricators

Using stainless steel fabricators does entail some considerations, including:

Quality Concerns

Some fabricators may compromise on quality to save costs. It's important to choose fabricators who prioritize quality and meet industry standards.

Lack of Experience

Some fabricators may lack the experience or expertise needed to produce high-quality stainless steel products.

Safety Concerns

Fabricating stainless steel can be hazardous. Fabricators must follow safety protocols and wear appropriate personal protective equipment to prevent accidents or injuries.

Environmental Concerns

Fabricating stainless steel generates waste and emissions. Fabricators should take steps to minimize waste and reduce their environmental footprint.

Ethical Concerns

Some fabricators may use unethical or exploitative labor practices. Choose fabricators who have a commitment to ethical labor practices and social responsibility.

It's important to note that these considerations are not unique to the United States, and they apply to stainless steel fabricators globally. In fact, the United States has laws and regulations in place to ensure that fabricators follow safety and environmental standards where other nations may not. Additionally, there are organizations and certifications that fabricators can obtain to demonstrate their commitment to quality and ethical practices.

Organizations Governing Stainless Steel Fabricators

There are, in fact, several organizations that regulate stainless steel fabricators in the United States. These organizations provide guidelines and regulations to ensure safe and effective fabrication practices. They also promote education and training for fabricators to ensure they have the knowledge and expertise needed to produce high-quality stainless steel products. Additionally, they provide a forum for sharing information and best practices, which helps to promote innovation and improvement in the stainless steel fabrication industry. These organizations include:

Occupational Safety and Health Administration (OSHA)

OSHA is a government agency responsible for ensuring safe and healthy working conditions for workers in the United States. They have established guidelines for the safe handling, use, and fabrication of stainless steel products to protect workers from potential hazards.

The American Welding Society (AWS)

The AWS is a professional organization that provides guidance and standards for welding and fabrication. They offer various certifications for welders and fabricators, including the Certified Welder (CW) and Certified Welding Inspector (CWI) certifications, which demonstrate a high level of expertise in welding and fabrication.

The Specialty Steel Industry of North America (SSINA)

The SSINA is an industry association that represents stainless steel producers, distributors, and fabricators. They provide guidance and resources for stainless steel fabricators, including the Certified Stainless Steel Fabricator (CSSF) program, which is a voluntary program that certifies fabricators who meet specific criteria related to knowledge, expertise, and quality.

The International Stainless Steel Forum (ISSF)

The ISSF is a global association that represents the stainless steel industry. They provide guidance and resources for the use and fabrication of stainless steel products, including the development of standards and guidelines for stainless steel fabrication.

Benefits of Stainless Steel Fabricators

Stainless steel fabricators offer many benefits, including customized products, superior quality, and long-lasting durability. They can also provide cost-effective solutions for various industries, from small businesses to large-scale manufacturing. These benefits are discussed below.

Customization

Stainless steel fabricators can create custom products that meet your specific requirements and specifications, allowing you to achieve a unique look or functionality that would not be possible with off-the-shelf products.

Superior Quality

Stainless steel is a high-quality material that is resistant to corrosion and wear, and stainless steel fabricators use their expertise to produce products with exceptional quality and precision.

Long-Lasting Durability

Stainless steel is known for its long lifespan and resistance to rust, corrosion, and staining, making it an ideal material for applications that require longevity and reliability. Stainless steel fabricators use their knowledge and experience to create products that will last for years to come.

Cost Effectiveness

While stainless steel products may have a higher upfront cost than other materials, their long lifespan and low maintenance requirements can make them a cost-effective option in the long run. Stainless steel fabricators can help you choose the right materials and designs to maximize the cost-effectiveness of your project.

Choosing the Proper Stainless Steel Fabricator

To ensure you have the most positive outcome when selecting a stainless steel fabricator, it is important to compare several businesses using our directory of stainless steel fabricators. Each stainless steel fabricator has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the fabricator for more information or to request a quote. Review each stainless steel fabricator business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple stainless steel fabricators with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

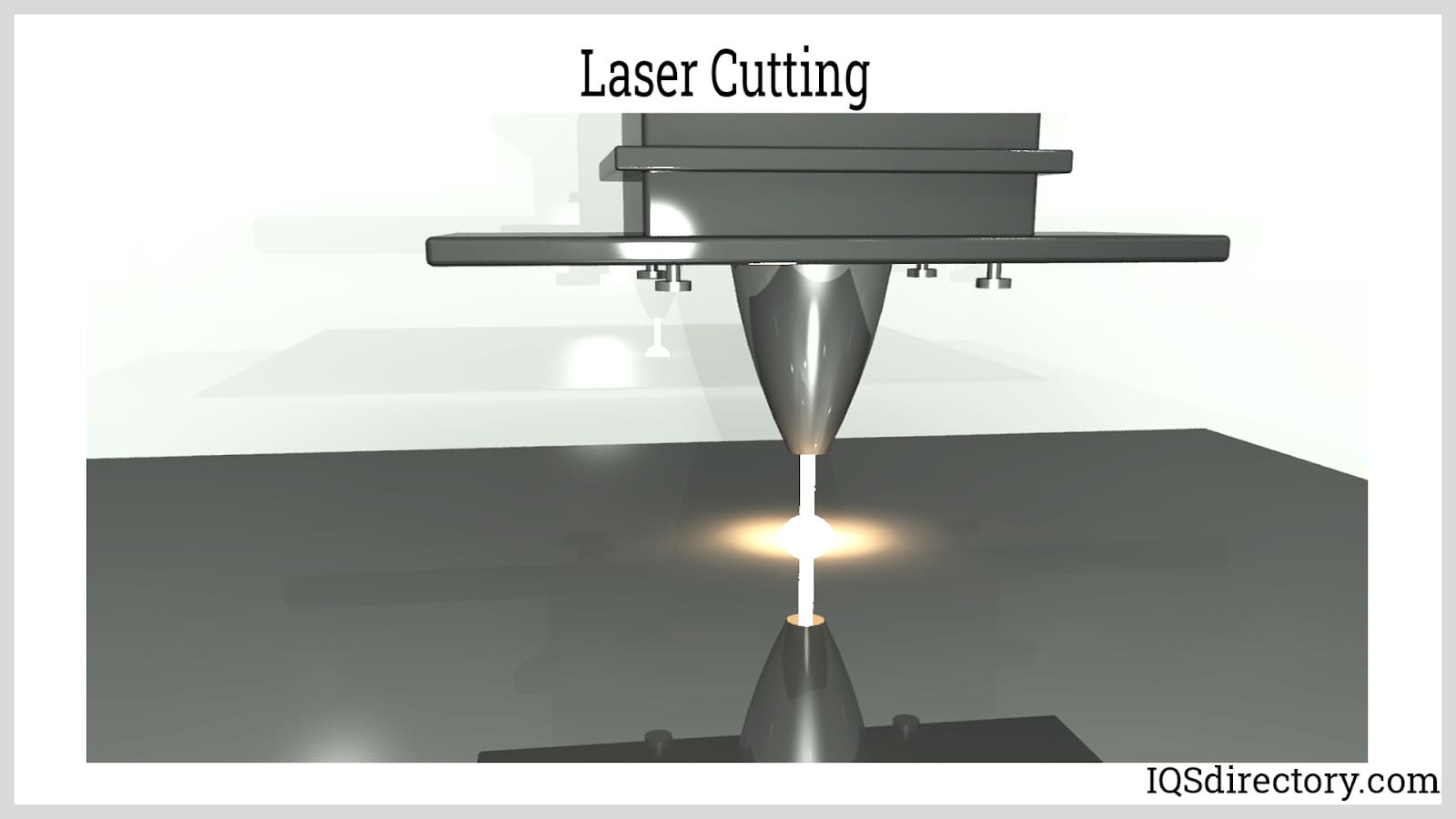

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services