A premier custom stainless steel fabricator solving complex challenges since 1951. We are a one-stop-shop offering advanced laser cutting (flat, tube, 5-axis), precision forming, and certified welding (GTAW, laser, robotic). We are ISO 9001:2015 certified and experts in stainless steel, duplex, and high-nickel alloys like Hastelloy.

At MET Manufacturing Group, we take pride in our expertise in metal fabrication, where precision, innovation, and craftsmanship come together to create durable and high-quality components. We specialize in transforming raw metal into complex parts and assemblies that serve a wide range of industries, from construction and transportation to energy and manufacturing.

At Kalamazoo Fabricating, we take pride in delivering high-quality metal fabrication solutions that bring precision, strength, and innovation to every project we undertake. We specialize in transforming raw materials into fully engineered components, assemblies, and structures that meet the exacting standards of our customers across diverse industries.

At Anchor Fabrication, we take pride in being a trusted partner for comprehensive metal fabrication solutions that serve a wide range of industries. We bring precision, efficiency, and craftsmanship to every project, combining advanced technology with years of hands-on expertise.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At Victory Machine & Fab, we take pride in delivering high-quality metal fabrication solutions that combine precision craftsmanship with advanced technology. We specialize in transforming raw materials into functional, durable, and custom-engineered components that meet the highest industry standards.

More Custom Metal Fabrication Companies

Comprehensive Guide to Metal Fabrication and Custom Metal Fabrication Services

Metal fabrication is a foundational process in modern manufacturing, involving the transformation of raw metal materials such as steel, aluminum, copper, and stainless steel into finished products. By utilizing advanced tools, cutting-edge equipment, and specialized techniques—including cutting, bending, welding, and assembling—metal fabrication enables the creation of essential components for diverse sectors. Industries ranging from construction, automotive, and aerospace to industrial manufacturing and energy all rely heavily on metal fabrication services for both standardized and highly specialized solutions.

Custom metal fabrication takes the process a step further, offering tailored solutions based on unique design specifications and project requirements. This approach is ideal for businesses or individuals seeking non-standard, bespoke metal products—whether for architectural accents, precision engineering, or creative applications. Custom fabrication combines the expertise of skilled fabricators with state-of-the-art machinery to turn detailed blueprints into reality.

What Is Metal Fabrication? Process Overview and Key Techniques

At its core, metal fabrication encompasses a series of processes that turn sheet metal, metal bars, tubes, and other raw materials into functional parts and assemblies. The most common metal fabrication techniques include:

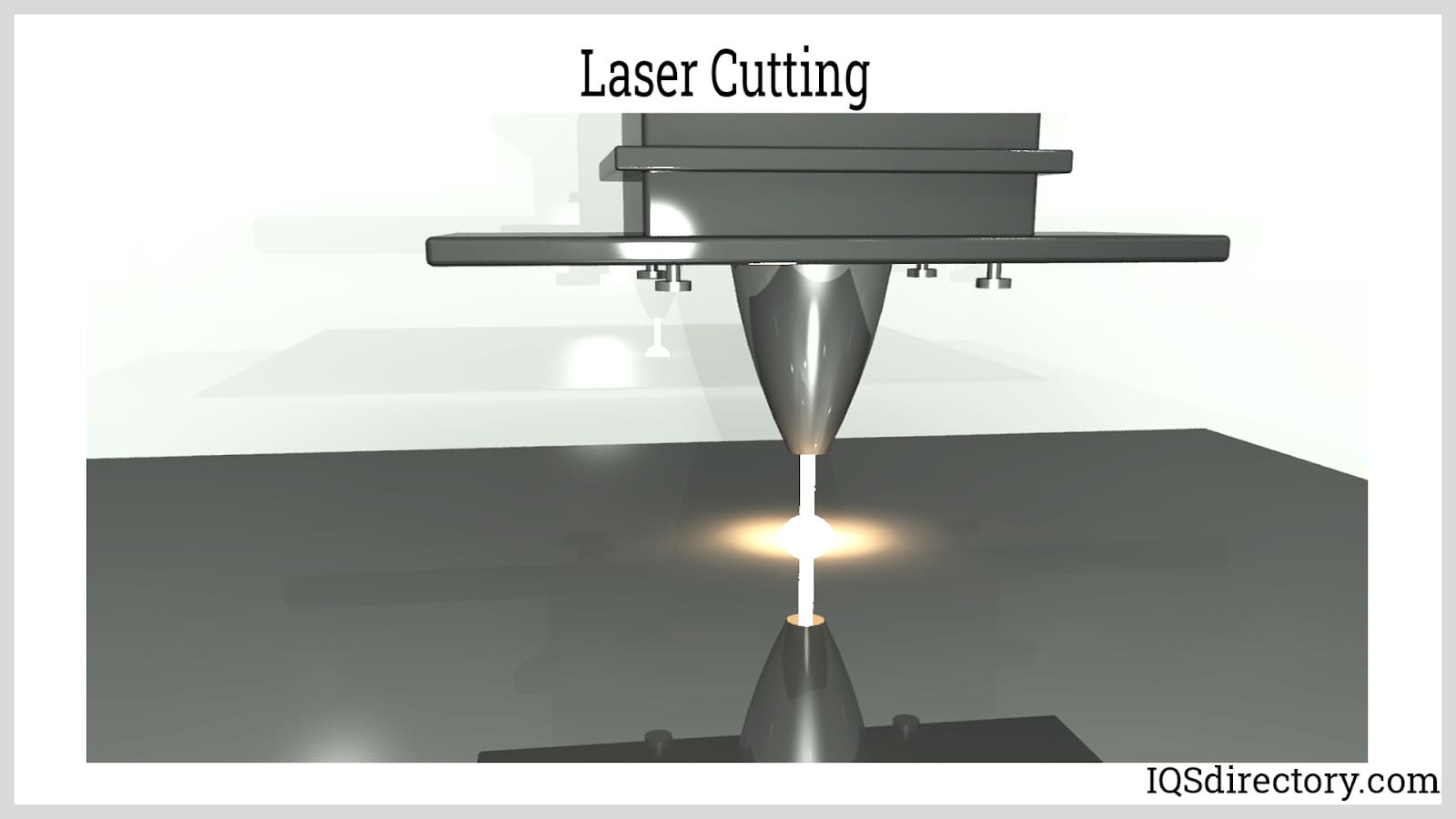

- Cutting: Laser cutting, plasma cutting, waterjet cutting, and shearing are used to achieve precise shapes and dimensions.

- Bending: Press brakes and rolling machines bend metal into the desired angles or curves.

- Welding: Various welding processes (MIG, TIG, stick welding) join metal pieces together, ensuring strength and integrity.

- Forming: Rolling, stamping, and forging give shape to metal workpieces.

- Machining: CNC machining, drilling, and milling refine components for high accuracy.

- Finishing: Processes such as powder coating, painting, sandblasting, and anodizing provide corrosion resistance and aesthetic appeal.

- Assembly: Components are combined to create finished products or sub-assemblies.

By coordinating these techniques, metal fabricators deliver robust solutions for everything from mass-produced industrial parts to intricate prototypes and one-off creations.

Considerations for Metal Fabrication Projects

When planning a metal fabrication project, several factors must be carefully evaluated to ensure optimal results. Here are critical metal fabrication considerations that influence both the process and finished product:

- Material Selection: Choosing between steel, stainless steel, aluminum, copper, or specialty alloys can affect strength, weight, corrosion resistance, and cost. Each material offers unique properties for particular applications.

- Design Requirements: Detailed engineering drawings and CAD models provide the blueprints for fabrication, impacting both feasibility and final appearance.

- Equipment and Tools: Access to advanced machinery—such as CNC plasma cutters, robotic welders, or automated press brakes—enables greater precision and efficiency.

- Production Volume: Whether you require a one-off prototype or high-volume production run, the scale will dictate setup, tooling, and turnaround time.

- Safety Protocols: Adherence to industry safety standards (such as OSHA or ISO) is essential to prevent workplace injuries and ensure compliance.

- Cost Considerations: Material costs, labor, complexity, and finishing requirements should be balanced against project budget constraints.

- Lead Times: Project timelines can vary based on workload, material availability, and fabrication complexity.

Unique Challenges and Considerations in Custom Metal Fabrication

Custom metal fabrication introduces additional layers of complexity to the standard fabrication workflow. Here’s what sets it apart and what you should know when sourcing custom metal fabrication services:

- Material Availability: Specialized or exotic metals may be needed for unique projects, impacting lead times and costs.

- Design Specifications: Highly detailed or complex designs may require advanced engineering, prototyping, and iterative feedback.

- Custom Tooling: Unique jigs, dies, or fixtures might be necessary to accommodate non-standard shapes and processes.

- Precision Requirements: Tighter tolerances and advanced quality control are often required to meet demanding specifications.

- Time and Cost: Custom jobs typically incur higher labor and engineering costs due to design, prototyping, and setup time.

- Collaboration: Effective communication between the client, designers, and fabricators is critical to ensuring expectations are met.

Benefits of Metal Fabrication and Custom Metal Fabrication

Top Advantages of Metal Fabrication

- Customization: Allows for tailored solutions to meet specific requirements.

- Durability: Metal products offer exceptional strength, longevity, and resistance to wear, corrosion, and extreme temperatures.

- Versatility: Suitable for countless applications, from heavy industrial machinery to fine art.

- Cost-Effectiveness: For large-scale production, metal fabrication can deliver strong ROI due to material efficiency and automation.

- Scalability: Capable of supporting both small-batch and mass-production projects.

- Recyclability: Metals are among the most recyclable materials, contributing to sustainable manufacturing practices.

Unique Benefits of Custom Metal Fabrication

- One-of-a-Kind Design: Achieve unique product features, branding, or architectural styles impossible with off-the-shelf items.

- Precision Engineering: Advanced tolerances, intricate cuts, and high-quality finishes for demanding industries like aerospace and medical.

- Material Optimization: Efficient use of specialty metals, reducing waste and maximizing performance.

- Improved Functionality: Solutions tailored to specific operational needs, often resulting in better safety, efficiency, or performance.

- Competitive Advantage: Stand out in your market with innovative, custom-designed products.

- Rapid Prototyping: Quickly evaluate and iterate designs before committing to full-scale production.

Wide-Ranging Applications of Metal Fabrication

Metal fabrication is integral to modern industry, with applications that span:

- Automotive & Transportation: Manufacture of car frames, chassis, body panels, engine components, exhaust systems, and more.

- Construction: Structural steel beams, reinforced concrete frameworks, staircases, railings, and architectural metalwork.

- Manufacturing: Production of heavy machinery, industrial equipment, conveyor systems, and factory automation components.

- Aerospace & Defense: Fabrication of precision aircraft parts, satellite structures, missile housings, and military vehicle armor.

- Energy: Creation of wind turbine components, solar panel frames, oil & gas rigs, and power generation equipment.

- Electronics: Enclosures, brackets, and heatsinks for consumer and industrial electronics.

- Food Processing: Stainless steel tanks, conveyors, and hygienic equipment for commercial kitchens and food manufacturing plants.

Looking for inspiration or examples of successful metal fabrication projects in your industry? Read our case studies to see real-world applications and results.

Expanding the Scope: Applications of Custom Metal Fabrication

Custom metal fabrication further broadens these applications by enabling creative, specialized, and high-performance solutions for a variety of industries. Common uses include:

Architectural and Decorative Fabrication

Custom fabrication is leveraged to produce eye-catching architectural features and bespoke decorative elements for residential, commercial, and public environments. Examples include:

- Metal screens, facades, and cladding

- Custom railings, staircases, and balconies

- Intricate metalwork for gates, fences, and signage

- Art installations and sculptures

Custom architectural metal fabrication allows designers to push creative boundaries while ensuring structural integrity and durability.

Medical Equipment and Devices

Precision and hygiene are paramount in medical settings. Custom metal fabrication helps produce:

- Dental and orthopedic implants

- Surgical instruments

- Custom medical carts and trays

- Diagnostic equipment enclosures

These highly specialized products demand tight tolerances and reliable performance—attributes custom fabrication delivers.

Custom Furniture and Fixtures

The interior design and hospitality industries often require custom metalwork for:

- Unique tables, chairs, and benches

- Lighting fixtures and shelving units

- Mixed material designs (metal with wood, glass, or stone)

- Retail point-of-sale displays

Custom metal fabrication ensures every piece is tailored to the client’s vision and space.

Artistic and Sculptural Projects

Artists and public spaces frequently commission custom metal fabricators to create:

- Sculptures, kinetic art, and interactive installations

- Metal murals, signage, and decorative panels

- Functional art (benches, lighting, fountains)

Metal’s adaptability and strength enable artists to realize complex, ambitious concepts.

Custom Automotive and Motorsport Components

Performance and aesthetics drive demand for custom automotive fabrication, including:

- Custom exhaust systems and headers

- Roll cages, chassis reinforcements, and suspension parts

- Body kits, spoilers, and unique trim pieces

- Motorsport safety equipment

Custom fabrication can enhance vehicle performance, safety, and visual appeal.

Industrial and Agricultural Equipment

Industries with unique operational requirements often rely on custom metal fabrication for:

- Conveyor systems and material handling solutions

- Customized industrial pumps, valves, and tanks

- Precision jigs, fixtures, and tooling

- Agricultural implements and attachments

Tailored solutions support productivity, safety, and equipment longevity.

Retail and Commercial Displays

To create compelling customer experiences, retailers use custom metal fabrication for:

- Clothing racks and shelving units

- Signage and branding elements

- Display cases and modular kiosks

- Interactive retail installations

Durable, attractive displays help brands stand out and drive sales.

Aerospace Components

Custom fabrication is crucial for aerospace and defense, supporting:

- Aircraft fuselage sections, brackets, and mounting hardware

- Fuel tanks and hydraulic systems

- Satellite and spacecraft structures

Extreme precision and certified materials are required for mission-critical applications.

Food and Beverage Processing Equipment

Custom stainless steel fabrication is the gold standard in food and beverage manufacturing, enabling:

- Bespoke kitchen workstations and counters

- Sanitary tanks, pipes, and mixers

- Brewery and distillery equipment

- Custom beverage dispensing systems

Fabricators adhere to strict health and safety standards, ensuring hygienic and durable solutions.

How to Choose the Right Custom Metal Fabricator for Your Project

With so many metal fabrication companies and custom fabrication shops to choose from, how do you ensure you select the best partner for your needs? Here’s a step-by-step guide to help your decision-making process:

- Define Your Requirements: Outline your project specifications, including material, tolerances, finishes, quantity, and timeline.

- Research Potential Fabricators: Use our directory of custom metal fabricators to compare companies with relevant expertise and capabilities.

- Review Their Portfolio and Experience: Look for fabricators with proven track records in your industry or application. Many showcase project galleries, certifications, and case studies on their websites.

- Evaluate Capabilities: Confirm access to advanced equipment (CNC, laser cutting, robotic welding), engineering support, and quality assurance processes.

- Check References and Reviews: Read client testimonials and third-party reviews to gauge reliability and service quality.

- Request Quotes and Proposals: Use our RFQ (Request for Quote) form to solicit detailed quotes from multiple fabricators. Compare pricing, lead times, and value-added services.

- Assess Communication and Support: Choose a fabricator who is responsive, collaborative, and transparent throughout the project lifecycle.

Ready to start your project? Contact multiple custom metal fabrication shops for quotes or expert advice on your specific application.

Frequently Asked Questions About Metal Fabrication

What industries benefit most from metal fabrication and custom metal fabrication services?

Industries including construction, automotive, aerospace, energy, electronics, medical device manufacturing, and food processing all rely on metal fabrication for essential components. Custom metal fabrication is especially valuable for industries requiring precision, durability, and unique design solutions.

How do I choose between standard and custom metal fabrication?

If your requirements can be met with off-the-shelf or catalog components, standard fabrication is often faster and more cost-effective. If you need unique features, specialized materials, or tight tolerances, custom metal fabrication is the best choice. Consider your project’s complexity, volume, and functional requirements.

What factors influence the cost of a metal fabrication project?

Key factors include material type, part complexity, required tolerances, finishing processes, production volume, and lead time. Custom projects typically involve higher engineering and setup costs. For a detailed cost breakdown, explore our guide to metal fabrication pricing.

What should I prepare before contacting a metal fabricator?

Have detailed drawings, material preferences, expected quantities, and timeline requirements ready. Clearly communicate your goals and any industry-specific standards your product must meet.

Is metal fabrication environmentally friendly?

Yes, especially when using recyclable metals and efficient manufacturing processes. Many metal fabrication shops adhere to green manufacturing practices and offer sustainable material options.

Still have questions? Contact our experts for personalized guidance.

Partner with the Right Metal Fabrication Company

Success in metal fabrication—whether standard or custom—depends on partnering with an experienced, reliable, and innovative fabrication shop. By understanding your needs, researching options, and leveraging our comprehensive online directory, you can connect with top-rated metal fabricators who deliver quality, value, and exceptional service.

Ready to take the next step? Request a quote for your custom metal fabrication project today and discover how our network of fabricators can bring your vision to life.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services